Details

BETTER THAN MECHANICAL CONNECTIONS,LESS LABOR AND COST

ESTWELD® SAFE high-voltage welds are permanent molecular bonds that cannot loosen or deteriorate, no maintenance is required and no resistance increase over time, so there is a continuous optimal electrical path. This makes ESTWELD® SAFE connections superior to traditional com- pression or mechanical connections that provide only surface contact between con- ductors and a less-than-perfect current path. In addition, ESTWELD® SAFE high- voltage welding system is easier to use and lower in labor cost, since you don’t need a certified welder. Full on site training can be provided by ESTWELD® SAFE Engineers.

|

|

A LOW EMISSION PROCESS

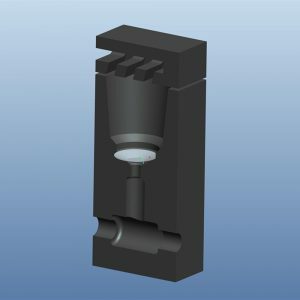

ESTWELD® SAFE high-voltage welding set-up uses a unique smoke filter system which prevents sparks and produces minimal smoke, but also reduces dust and other emissions to an acceptable level for exposures, even if used in unventilated small rooms and cable tunnels.

ESTWELD® SAFE welding is a reliable method of quickly making electrical connections.

OPTIMUM STANDARDIZATION:

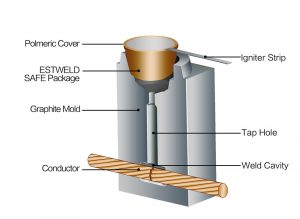

Welding equipment (crucible, smokefilter body, frames, etc.) is standardized and can be used on all connections. Only different molds and different types of welding material are needed for Copper welds.

ESTWELD® SAFE connections give you a single process for making all cable-to-cable, splices and terminations connections.

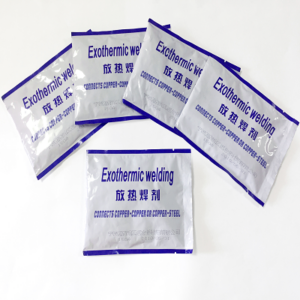

The welding material contains copper and aluminum oxide as well as additional ingredients.

The ignitor starts an exothermic reaction inside the crucible, producing the molten copper or molten aluminum. The molten material then flows from the crucible into the mold, welding the ends of the conductors to create the molecular bond.

ESTWELD® SAFE High-Voltage System Advantages:

ESTWELD® SAFE high-voltage welding system can weld different sections copper cables.

ESTWELD® SAFE connections can be made easily with minimal training.

ESTWELD® SAFE weld is small –handling is simple after welding

Specially designed weld profile for high-voltage applications.

No external power or heat source required.

Has a current carrying capacity equal to that of the conductor.

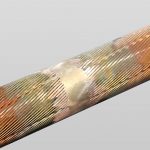

Permanent molecular bond will not deteriorate with age, cannot loosen or corrode.

Will withstand repeated faults, is made with lightweight equipment, has low labor cost and is time saving on jobsites.

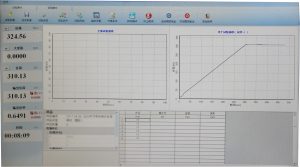

Strength results

In laboratory tests, the tensile strength of ESTWELD® SAFE high-voltage cable connections proved to have overall strong results. The tests show on average that the ESTWELD® SAFE connection provides about 75% tensile strength compared to the cable by itself. Test results vary between approx. 60% up to 90% tensile strength, whereby the breaking point is annealed cable at the edge of the ESTWELD® SAFE weld.

|

|

Performance results

Like ESTWELD® SAFE connections, their permanent low resistivity provides a current-carrying capacity that’s greater than the conductors.

|

|