Details

|

|

|

|

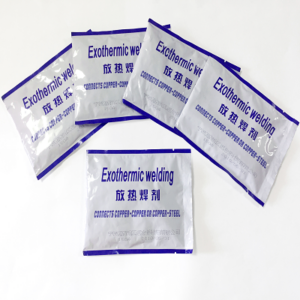

ESWELD® WELD POWER

ESTWELD® weld power is a mixture of copper oxide and aluminium , packaged by size in individual plastic tubs or bags.

Each tube contains the starting material in the lid ,with weld power in the cacuum aluminum foil bag .

These containers are packaged in plastic boxes with the corresponding metal disks. Each weld uses one disk.

These materials are not explosive and not subject to spontaneous ignition.

The following is for refrence:

| Part Number | Qty(pcs) | Weight(kg) |

| 15E20A | 20 | 0.015 |

| 25E20A | 20 | 0.025 |

| 32E20A | 20 | 0.032 |

| 45E20A | 20 | 0.045 |

| 65E20A | 20 | 0.065 |

| 90E20A | 20 | 0.090 |

| 115E20A | 20 | 0.115 |

| 150E20A | 10 | 0.150 |

| 200E20A | 10 | 0.200 |

| 250E20A | 10 | 0.250 |

ESTWELD®– The Molecular Bond

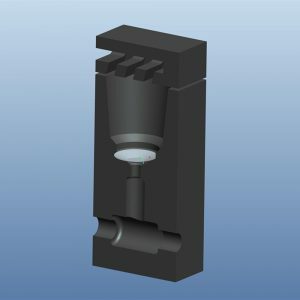

The ESTWELD®process provides a way to produce copper to copper, copper to steel molecular bonds with no external energy or heat source.

The principle consists of bringing together a welding materials and ignition agent in a suitable graphite mould. The reduction of copper oxide by aluminium produces molten copper and aluminium oxide slag at extremely high temperatures.

The shape of the mould, its dimensions, and the size of the welding material, are all dependent on the items to be welded.

Installation Is Easy

Step 1 : Position cleaned conductors in mold after making sure mold is dry, by pre-heating or making a test joint. |

Step 2 : Place metal disc in bottom of mold crucible. |

Step 3 : Dump weld powder into crucible. |

Step 4 : Sprinkle the starting powder over the weld powder and onto the lip of the mold.Close the cover. |

Step 5 : Ignite the starting powder with the Flint Ignitor. |

Step 6 : Remove weld and clean mold before making next connection. |